Commercial Slicers, Dicers and Cutters Buying Guide

Posted by CHERIE THOMPSON

Cutting fruits and vegetables to a consistently uniform size with minimum waste by hand takes time, effort and skill. Chefs would far rather be doing something more productive.

Manual food processors make kitchen prep quick and easy by dicing, cutting, coring, peeling and slicing ingredients, all without electricity. Not only do you get reliably uniform cuts with minimum waste but also the size consistency helps to ensure even cooking as well. They require minimal counter space and reduce labour needs.

There is a wide range to choose from. There are models that have interchangeable blades that can do a variety of operations. Others are more specialized with models specifically designed to slice tomatoes, peel and dice pineapples or even make onion flowers. We have a wide selection of manual food processors available to help your kitchen speed through prep.

Types of Manual Food Processors: Slicers, Dicers and Cutters

All Purpose Manual Food Processors

The most common all-purpose design is an inverted sledge-shaped metal frame with the blade set top-centre. A handle or plunger attached to a push-block is guided down to the blades by a pair of rods, usually stainless steel. The sled design gives a handy area under the blades to put a container to receive the processed items. Unscrewing a couple of wingnuts is usually all that is needed to remove a blade and install another. The all-metal frame and splayed legs give these models impressive strength and stability.

All-purpose models owe their versatility to their interchangeable blades. One blade for slicing, another for making wedges, one for small dice, another for larger dice and so on.

Good models can handle almost any fruit or vegetable you care to mention. Harder vegetables, like sweet potatoes, especially in large quantities, may stretch the tolerance limit of some models.

Commercial Manual Slicers

All purpose manual slicers are popular in many foodservice kitchens for consistency and to save time. Also a favourite of staff who must slice kilograms of onions. Swapping out the blades, instantly changes the thickness of the slices. Simple to use and easy to clean, these units can easily be tucked away when not in use.

Mandolines

Mandolines have been around for ages and for very good reason. They are inexpensive, compact and can be stored away in a drawer when not in use. They can slice, julienne and make french fries, potato chips and waffle slices. Not bad, eh? For small volumes a good mandoline is a very handy kitchen tool. Even inexpensive plastic models are surprisingly durable and easy to use.

There are two standard designs; handheld and stand styles.

Handheld mandolines are smaller, with a handle at one end that you hold while the other hand pushes the food item back and forth across the blades.

Mandolines with supporting stand is for improved stability. These mandolines tend to be larger, more robust and the frame is usually made of stainless steel. However some great quality ones can be made of plastic.

Mandoline blades are made from stainless steel. They can be straight, diagonal or V-shaped. Some have adjustable or interchangeable blades.

For the frame, you have a choice of plastic or stainless-steel. Whichever one you choose ensure it has a good cutting guard - to keep finger tips off the menu!

Manual Rotary Slicers

Here, we’re talking about a manually operated rotary style of slicer that can handle fruits and vegetables. Easy to use, this style of slicer is simple yet effective, creating consistently sized slices of fruits and vegetables.

Simply fill the hopper/trough behind the blade with produce and start turning the wheel. Again, due to it's size and no need for electricity, this slicer can move wherever the work needs to be done.

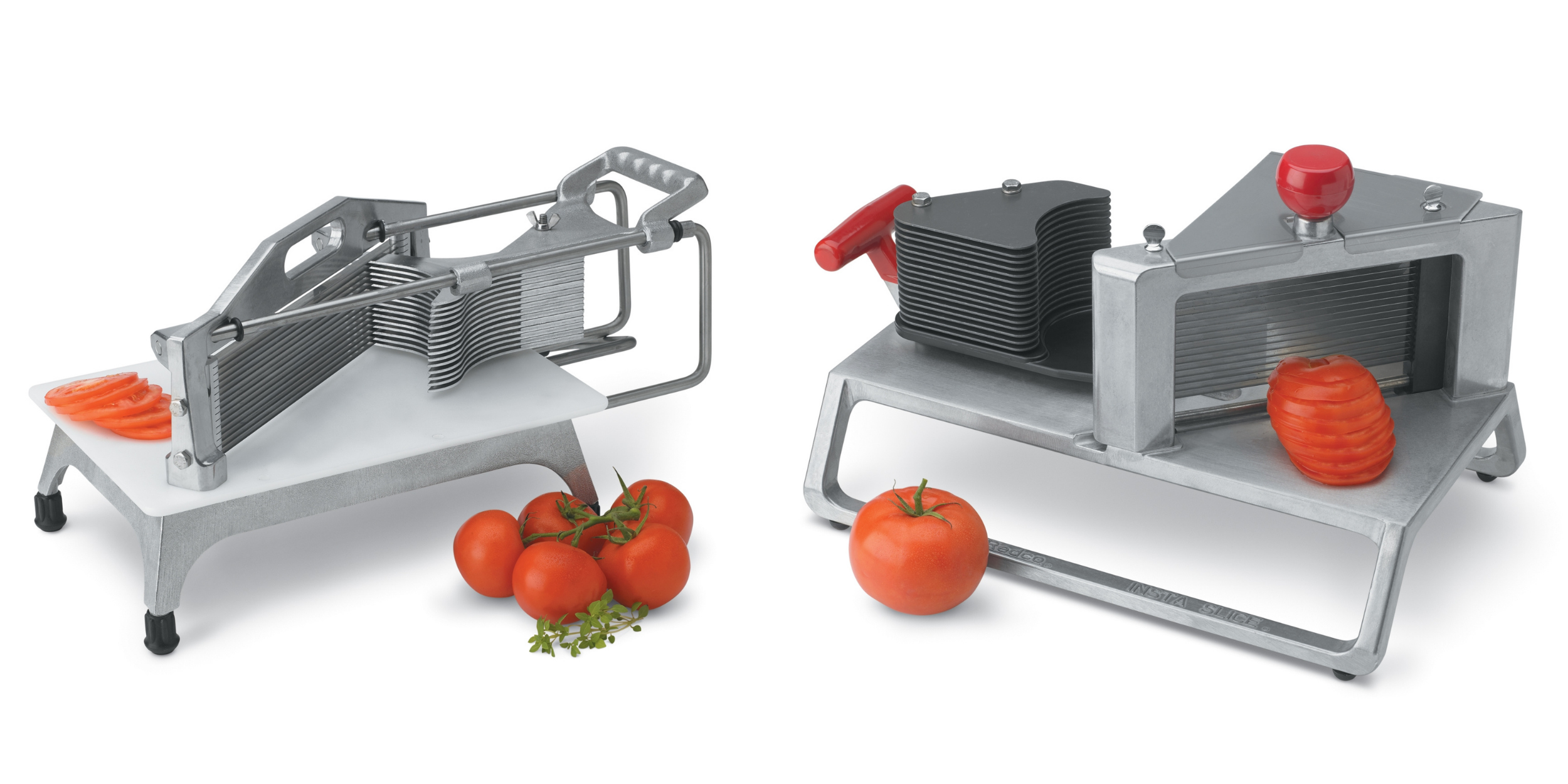

Commercial Tomato Slicers

Ripe tomatoes are not easy to slice except with the sharpest blade; they tend to squash. Tomato slicer blades have razor-sharp edges specifically designed to zip through tomatoes without squashing a single one. Of course, you can use them to slice most other fruits and vegetables to justify the cost, but you run the risk of dulling those super-keen blades. For foodservice operations that call for large quantities of sliced tomatoes, it's a perfect choice.

Commercial Manual Cutters

If there’s a category of fruit or vegetable or a particular shape you want them cut into there’s probably a machine to help you do so.

For busy bars and pubs there are wedgers for lemons, oranges or limes. There are models that will peel and core pineapples or apples. Models with a dome-shaped push-block are specifically for slicing or dicing onions.

Manual French Fry Cutters

One of the most popular manual food processors is the French fry cutter. Cutting a lot of potatoes into fries is going to test the limits of even the best all-purpose food processor: the blades will eventually become dull or, worse, bend and warp. .

Making loads of fries? A good french-fry cutter would undoubtedly be a wise investment. For more details check out our guide on How to Choose a Commercial French Fry Cutter.

Commercial Manual Dicers

Manual dicers designed for commercial kitchens save valuable time and money. Determine dice size and install the correct blades, put the produce in the hopper, crank the handle while using the pusher to feed the product to the blades and out comes your diced finished product.

Some manual food processors are advertised as “dicers” they don’t, strictly speaking, dice - at least not in a single operation. You have to pre-slice the fruit or vegetable first, then lay the slices on the blades for cutting into dice. What you’re really doing is cutting very short strips. Even so, this is a quick and efficient way to make perfect dice.

Manual Food Processor Features to Consider

Material

In any busy kitchen you have to depend on the reliability of your equipment. Fortunately, commercial manual food processors are generally sturdily-built and reliable. All-purpose models have virtually indestructible aluminum or stainless steel frames.

Hand-held mandolines are often all plastic, save for the blade, to keep them manageably light. With normal use they will survive the harsh kitchen environment. Although, an all stainless steel model may be better suited to your operation.

Blades

The crucial components are the blades. Blades should be strong enough to handle all but the hardest food item repeatedly without dulling. Even so, it’s probably wise to have an extra set just in case. It should be possible to swap out one blade for another easily. Then you can go from slicing to wedging in a couple of minutes.

Also check on the availability of replacement blades and different types of blades (and paired push-block) when you make your purchase.

Counter vs Wall-mounted

Short of counter space? Wall-mounted cutters may be your answer. All you need is a couple of feet of wall space that not being used for anything else. Another advantage is that the processed items can fall directly into a container of any size you like, placed directly below.

Stability

The more conventional countertop models have to be reliably stable when in use, especially on wet stainless steel work surfaces. The sled design of most models adds some stability, aided and abetted by skid-resistant feet or suction cups. Some models can be bolted down, which would certainly solve the stability question, but of course these can’t be conveniently stored away when not in use.

Any way you slice, cut or dice it, manual food processors built for commercial kitchens save valuable time and labour and give your menu items consistency.

Written by Charles Bruce-Thompson

Shop our entire collection of Slicers, Dicers and Cutters