Bun Pan and Rack Buying Guide

Posted by CHERIE THOMPSON

We like to bake buns and we cannot lie. And cookies and roast veggies and toast hazelnuts and cook pounds and pounds of bacon. All of it is possible with one kitchen essential – a bun pan.

Bun pans, sheet pans, cookie sheets or baking sheets, they may have many names, but foodservice operators would be lost without them. Add silicone bun pan liners and bun pan racks, this dynamic combo can bake, roast, store, stack and rack day after day.

Here’s what we will cover in this article:

• What is a Bun Pan?• Bun Pan Sizes

• Bun Pan Materials

• Bun Pan Features

• What are Bun Pan Racks?

• Bun Pan Rack Sizes

• Bun Pan Rack Materials

• Bun Pan Rack Features and Accessories

• Chef Tips for Using Bun Pans

What is a Bun Pan?

At its most basic description, a bun pan is a flat sheet of metal designed for high temperature use in the oven. Depending on its use, the flat sheet may have one or more upturned edges. Bun pans, sheet pans and baking sheets have all four edges upturned which makes them ideal for many uses in the kitchen.

Although the name cookie sheet is sometimes used interchangeably with bun or sheet pan, cookie sheets typically have just one upturned edge. This unique feature allows the baker or pastry chef to easily grab the pan from the oven and slide the cookies right off the sheet onto a cooling rack.

Bun pans are used for more than just baking. You will run out of pans before you run out of jobs they can help with.

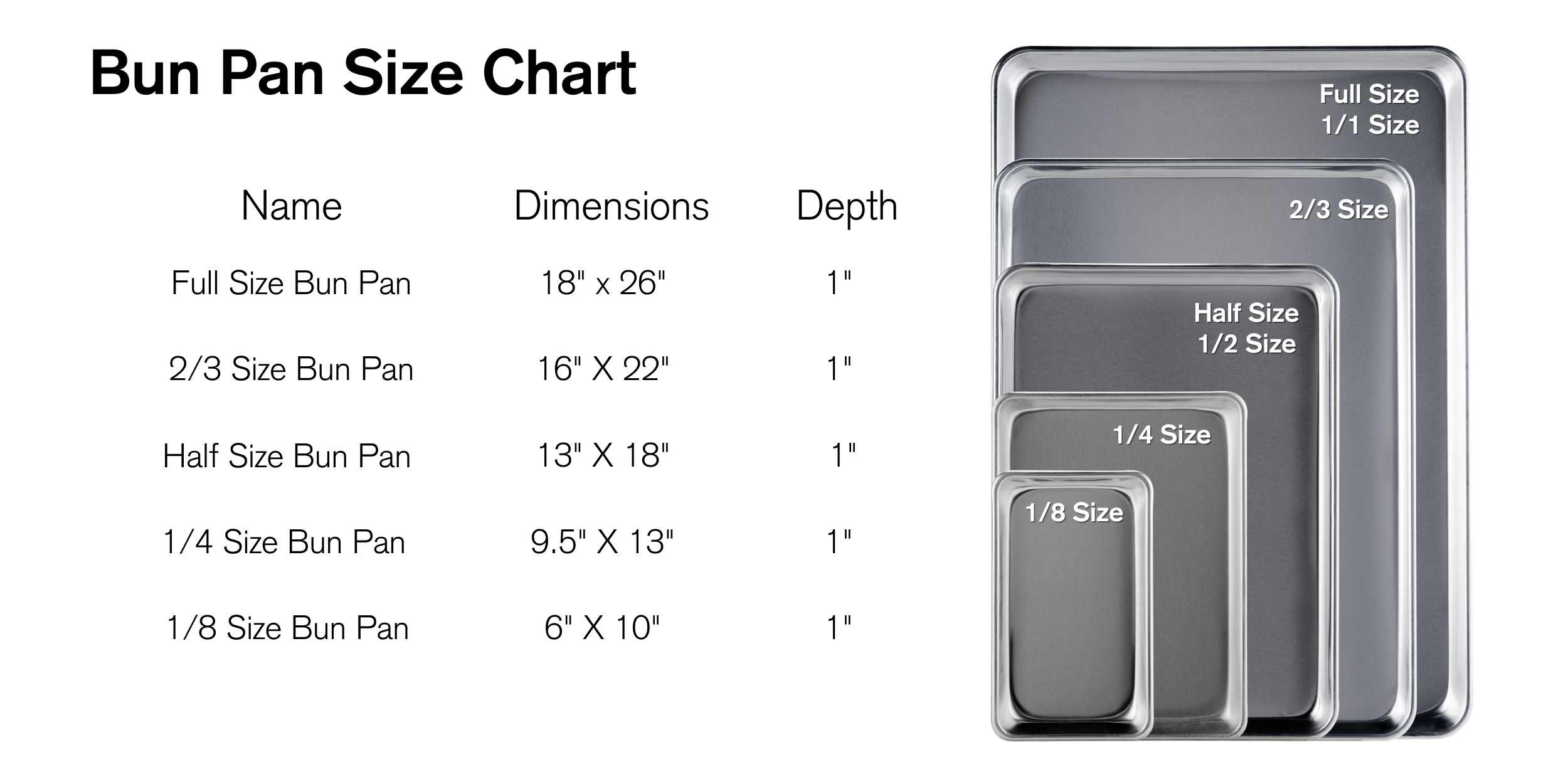

Bun Pan Sizes

Commercial baking sheets have standardized sizing, making it easy to use throughout the foodservice industry. Although there may be slight variations between manufacturers, chefs know that a full size bun pan is the same no matter who makes it or what kitchen they are working in.

The size you need depends on your equipment, what you are making and how you need to store them. Here are pan names and average standard measurements. Most bun pans are 1” deep.

Bun Pan Materials

Aluminum

Efficient heat conducting makes this baking pan material the top choice of most chefs and bakers. That means the pans heat up and cool down fast. Because of its naturally light colour, aluminum pans promote minimal browning, keeping your cookies the perfect golden brown.

Aluminum can be scratched, so, do not cut foods on your pans; remove to a cutting board instead to maintain the pan's surface. Also, remember that aluminum doesn’t like acidic foods as they can cause discolouration and pitting when in contact for long periods of time. Using pan liners can help avoid this issue – not to mention make cleaning up easier.

Stainless Steel

Although extremely durable, stainless steel is a poor conductor of heat. However, stainless steel is resistant to stains and looks great even after repeated use. This allows these pans to go from oven to display.

Nonstick Coated

These bun pans have a finish that is designed to minimize the amount of fats and oils needed to bake, roast and cook food items. Nonstick coated pans are typically aluminum with a nonstick coating applied to the interior of the pan. Nonstick pans tend to be darker in colour which lead to crisp and browned crusts. Bake times and/or temperatures may need to be adjusted to compensate. Nonstick pans need to be treated with care to minimize damage to the coating.

Bun Pan Features

Gauge

The gauge refers to the thickness of the metal used to make the sheet pan. The lower the number, the thicker the metal. We know, it doesn’t make sense, but that’s just how it is. The thicker the gauge the more durable the bun pan and less prone to warping, scratching and denting.

Edges

There are multiple types of edges available for bun pans each with pros and cons.

Flat/Rimless

Exactly what you think it means, these sheet pans have no rims or at least one side with no rim. This feature allows bakers to easily slide baked goods off the baking tray onto a cooling rack or onto displayware.

Rimless sheets have limited use as they cannot contain batters or liquids.

Tapered

These edges or sides are angled. Two benefits to this feature are the ability to contain batters and liquids and the ability to stack pans of the same size. A space saving necessity for most kitchens.

Rolled

The baking tray edge is rolled under. The sides are typically also tapered. Rolling the edges increase the stability of the pans and they keep their shape after repeated use.

Rolled Wire Filled

Going a step further than the rolled edge, these pans have wire rolled into the edge adding even more stability and reduction in warping under high volume conditions. Also, the bun pan can be referred to as wire rimmed bun pans.

Open

The edge of the sheets are curled and left open. The curl assists in keeping the shape, but with the open curl it allows for easy cleaning as no food can get trapped.

Solid and Perforated

Most kitchens predominantly use solid bun pans because of their range of uses. However, perforated pans with holes in the bottom promote air circulation and are popular among bakers because they give a crispier crust. The increased air flow also can slightly decrease bake times which can save hours in the long run.

What are Bun Pan Racks?

Pan rack, roll rack, rolling kitchen rack, bread rack, sheet rack, sheet pan rack...that is a lot of nicknames, but when everyone loves you and you are that important it doesn't matter. Designed to hold full size and half size bun pans for storage and transport, these convenient space savers are a foodservice favourite.

Bun pan racks can be mobile or stationary and are available in a variety of sizes and styles.

Bun Pan Rack Sizes

Racks sizes are standardized to match the pans. Again, allowing chefs and bakers to know that no matter the kitchen, a full size baking sheet is the same and will fit in the rack.

There might be slight variations between manufacturers, however there are two main sizes of racks.

Half Size - 26” high x 20” wide x 26” deep

Full Size - 69” high x 20” wide x 26” deep

The number of pans a rack can hold is typically evident in the name of the product. It might say 20 pan or 40 pan but it might also say 20 tier or 10 tier. The number indicates the amount of full size baking trays it can hold.

The number is determined by the amount of slides in the rack. The spacing of the slides within the rack determines how many will fit. Just because it says it holds 20 full size pans doesn’t mean you can fit 20 pans if the food on your pan is taller than the space between the slides.

Bun Pan Rack Materials

Aluminum

Light weight but durable, these racks are a cost effective option popular with most foodservice businesses.

Stainless Steel

Extremely durable and easy to clean with their smooth surfaces, these racks can typically hold more weight but are also more expensive.

Plastic

Some operations prefer using plastic bun pan racks. Strong enough to withstand use in demanding kitchens but with a different look and feel than either aluminum or stainless steel. These racks have rounded corners and even bumpers to product walls, doors and equipment.

Bun Pan Rack Features and Accessories

Loading

End loading or side loading are the options here. End loading means the opening to slide the trays in will be on the short side of the rack. Side loading means the opening to slide the trays in will be on the long side of the rack. Side loading is great for catering and when full size pans are the norm as it is easier to load the rack.

Supports

The overall stability of the rack is based on the amount of supports and their location. For the best stability look for a minimum of 6 supports in a full size rack, usually two each on the top, middle and bottom.

Regardless of the number of supports, always check the manufacturers details about the weight capacity of the rack. You need to understand the total weight capacity and the weight capacity per shelf.

Casters

Casters, also called wheels, are a key feature to racks making it easy to transport your goods wherever they need to go. Larger wheels allow for stability, and make it easier if moving between several different floor materials. Non marking wheels keep your floors clean and also reduce the noise level when moving the rack.

Ensure there are at least two locking casters to keep the rack where you want it and for increased safety - of its contents and for staff.

The weight capacity of bun pan racks are determined by the strength of the casters (and the shelves/slides).

Bun pan racks are also available without casters to be put into reach-in refrigerators or freezer, under equipment or in more permanent locations. And there are some available for wall-mounting.

Bun Pan Rack Covers

Bun pan rack covers are designed to protect your racks, pans and the foods they hold from debris and contamination. They can also be used to assist with proofing dough as these covers reduce temperature fluctuations from drafts and maintain humidity. Clear covers let you see the contents and zippers make access easy.

Packaging

Roll racks can be shipped assembled or unassembled. It is more cost effective to purchase an unassembled rack if you have the time and labour available to put them together on-site.

From commercial bakeries, small cafes and high-volume cafeterias to fine dining establishments all foodservice kitchens need bun pans for many types of cooking and baking – from sweet to savoury. Remember to have an adequate stock of multiple sizes on hand and the racks to stack and roll.

Chef Tips for Using Bun Pans and Bun Pan Racks

• Remove food from pans before cutting.• Allow pans to cool completely before washing.

• Hand wash only to maintain quality.

• Use bun pan liners for even results and easier cleanup.

• Use silicone bun pan liners for sustainability.

• Fill a rack from top to bottom to reduce chance of contamination onto the pan contents below.

• Whenever possible, put the heaviest bun pans closer to the bottom for safety.

• Adhere to the maximum weight capacity per shelf on the rack.